Analysis for High Performance Composite Products

Services // Analysis // Composites

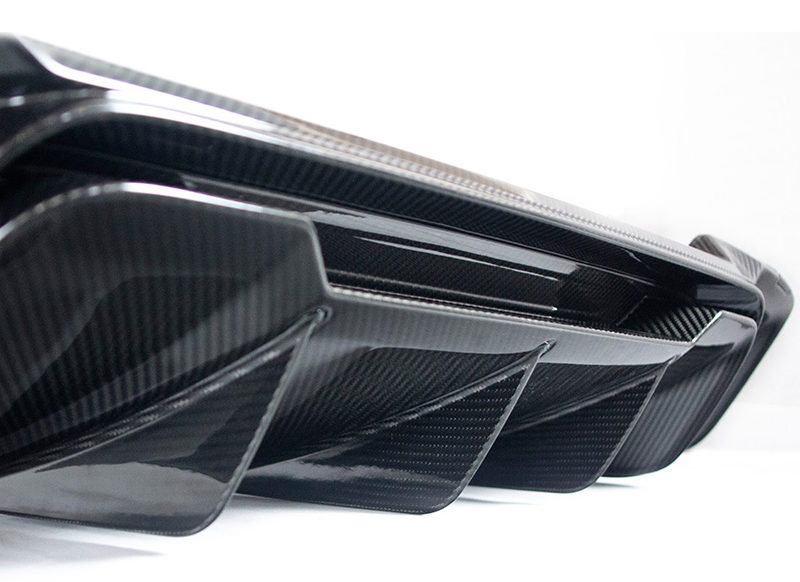

Having worked on composite structures with major automotive and aerospace companies for over a decade, Calcate engineers are able to provide their customers with the latest composite analysis and optimization. This experience coupled with advanced simulation tools allows us to efficiently develop high-performance and light composite structures.

To really take advantage of composite materials, our engineers perform a feasibility study to assess the requirements, loads, attachments, mating parts and the environment to determine how the benefits of composites can be leveraged. Often, it is the priority of the key drivers like cost, weight, complexity, performance, and part count that determines the design and manufacturing approach. Once the design approach is determined, our engineers perform detailed simulation analysis and optimization to guide our customers to light weight and high-performance designs.

Composite Analysis & Optimization

- Material characterization (material cards)

- Static, dynamic & Crash analysis

- Ply and laminate creation & optimization

- Adhesive bonding assessments

- Energy absorption capability

- Failure modeling and assessment

Material Selection

An important step that we often perform for our clients is a material selection to confirm that composite materials are a perfect fit for their product. Our comparison often with metals include:

- Performance & weight

- Life cycle cost

- Timelines

Let’s Talk About Your Needs

See how our advanced engineering services can improve your project