FATIGUE & DURABILITY

Advanced Methods for Predicting Durability

Structures that experience dynamic or repetitive static loads need to be assessed for fatigue analysis to prevent premature failures. Calcate engineers have fatigue analysis experience in a wide range of industries including consumer goods, industrial equipment, automotive and aerospace structures.

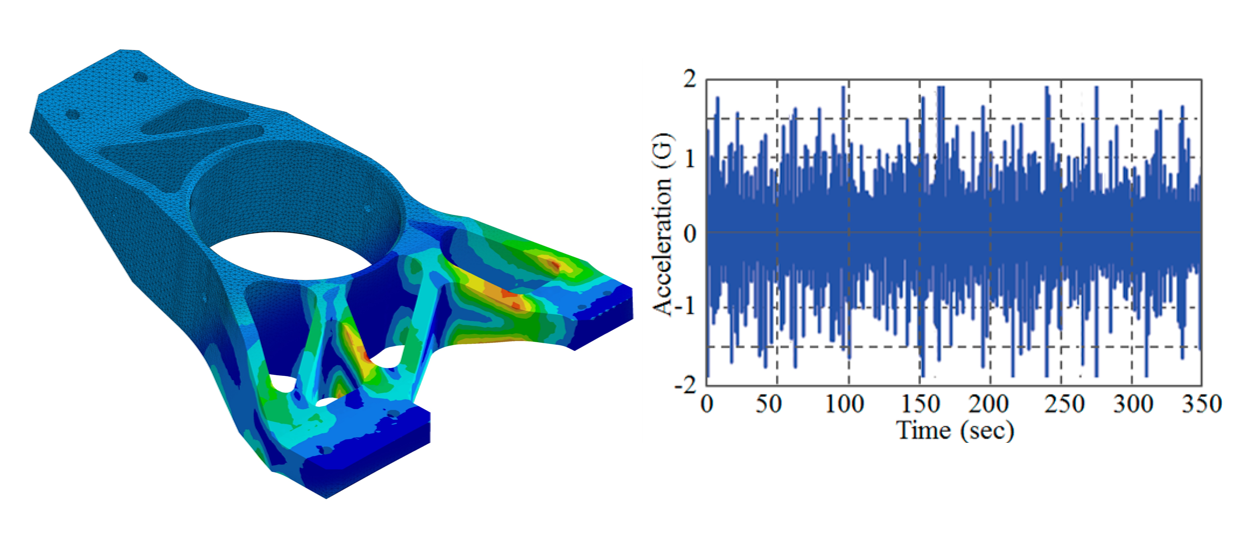

At Calcate we perform fatigue analysis of metals and composites by first creating an FEA model and applying the cyclical fatigue loads to obtain stress and strain. We then use industry standards to interpret these stresses and strains to calculate the fatigue life of the structure. We can efficiently use static loads or transient event data (vehicle driving on rough terrain, vibration, etc) to perform fatigue life or damage predictions. Performing fatigue assessment at the early stages of design prevents costly fatigue failures, design changes, and re-work later on.

Fatigue Analysis Types

- Endurance limit analysis :

-

- Infinite life

-

- Stress-based analysis:

-

- High cycle fatigue (S-N curves)

-

- Strain-based analysis:

-

- Low cycle fatigue (E-N Curves)

-

- Fracture Analysis:

-

- Fatigue crack growth

- Residual life

-

Standards Experience

- British standard BS 7608 – 2015: Steel Fatigue

- British standard BS 8118 – 1991: Aluminium Fatigue

- EN 1993-1-9 Eurocode 3: Design of steel structure

Let’s Talk About Your Needs

See how our advanced engineering services can improve your project