Optimizing Design for Manufacturing Success

Services // Design // Detailed Design

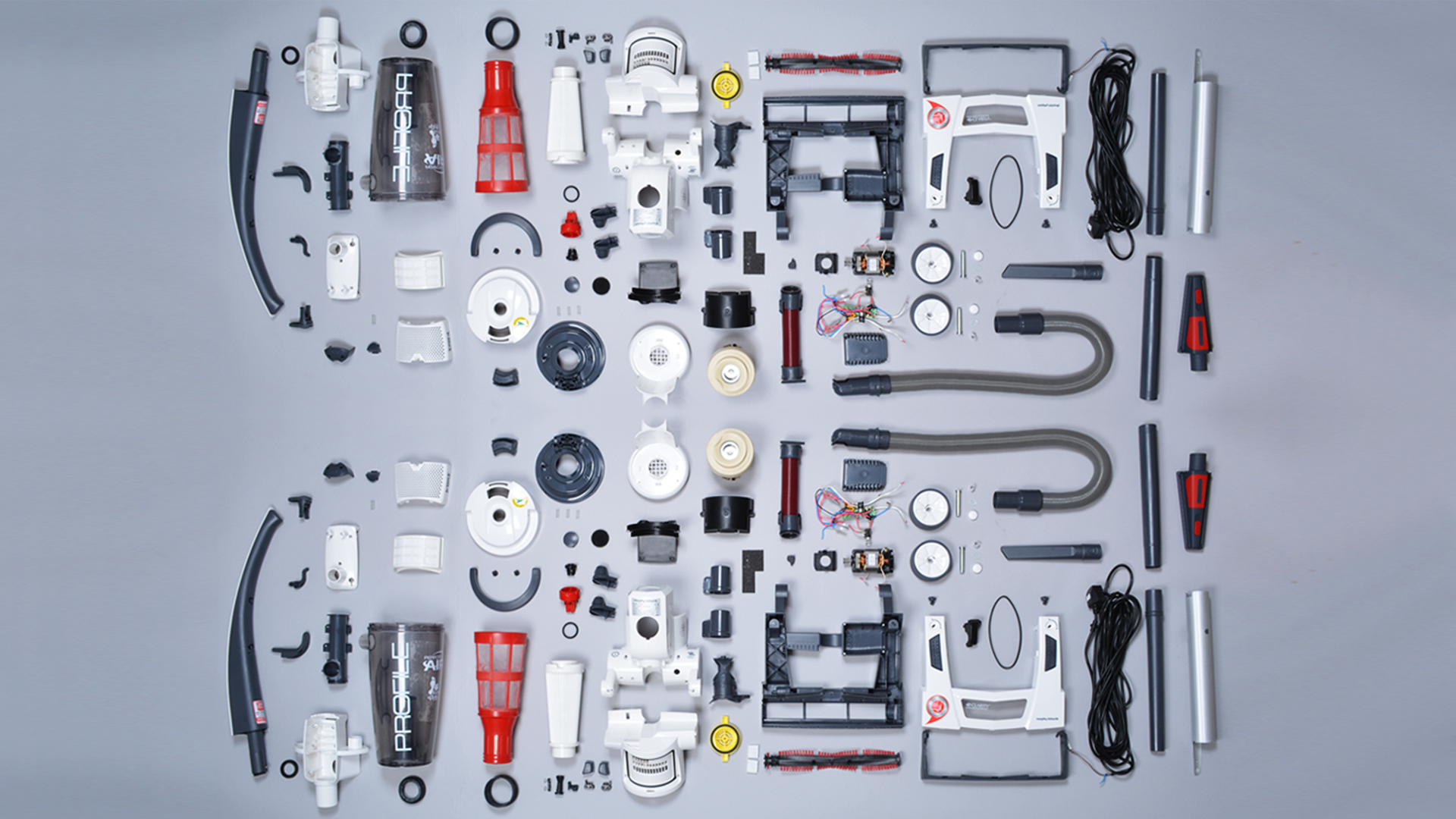

In the detailed design stage, the design team completes the design and produces a detailed specification of each part and assembly. Once the general sizing and analysis is complete, manufacturability and assembly need to be examined and optimized.

Calcate has extensive design experience in this phase of product development. We perform structural analysis including static, dynamic and fatigue to verify that the detailed design meets the appropriate lifecycle requirements while minimizing manufacturing and assembly costs.

Design for Manufacturing

A good detail design includes design for manufacturing during the detail design to reduce total life-cycle costs and meet deadlines. At Calcate, we are experienced in:

- Manufacturing processes

- Material selection

- Manufacturing tolerances

- Engineering drawing

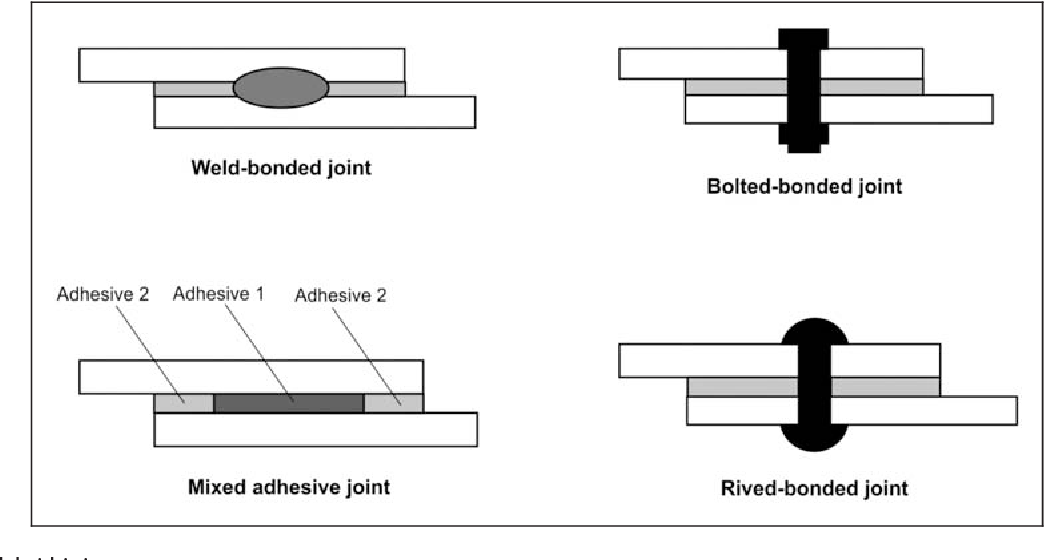

Joint Design and Analysis

In structures, the most common failures occur at joints. Calcate engineers are experts in sizing joints using analysis during the detail design phase. Our engineers are experienced in designing and analysing various types of connections including:

- Bolted: Calcate engineers have the required expertise to select the correct type of connection (slip critical & bearing) for a given application, as well as the correct bolt sizing, grade, numbers and spacing.

- Bonded: We have the expertise needed to design structural joints for use with structural adhesives. Our engineers optimize bonded joint for geometry, materials and loading in industries ranging from aerospace to consumer products.

- Welded: Structural weld joints depend on the type of joint (butt, corner, edge, lap, tee), dimensions, parent material. We have the experience needed to select the most appropriate welding method for the desired application.

Let’s Talk About Your Needs

See how our advanced engineering services can improve your project