Validate Analysis Predictions With Test Correlation

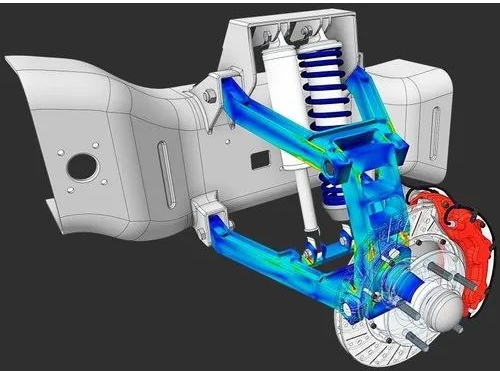

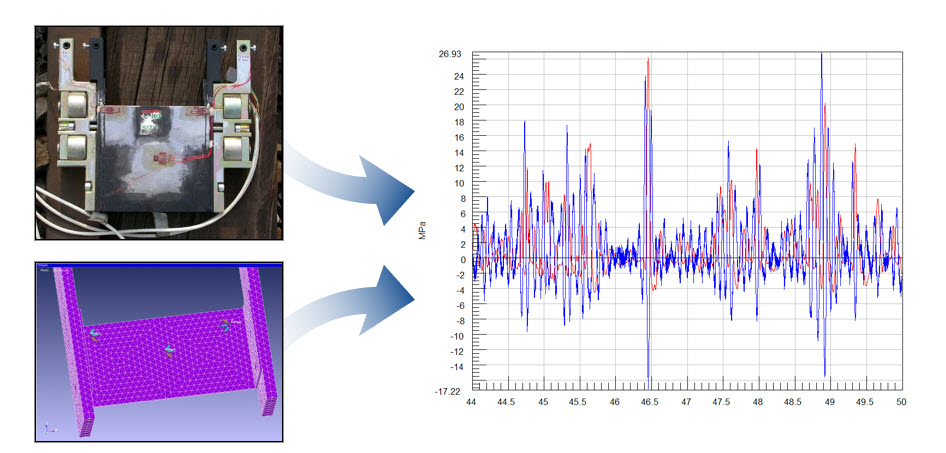

Analysis models predict component response to forces and environmental conditions – but only when the model matches the physical structure. Using testing to correlate the finite element model (FEM) to the physical structure is an important step in building confidence in the model’s predictive capability.

Test-analysis correlation is the process of modifying the FEM in order to minimize the differences between the FEA predictions and test results. At Calcate, our engineers have a wide range of experience in performing test-analysis correlation in all phases of testing including test preparation and post-certification. A correlated and accurate FEM helps our customers cut development costs while shortening the time from concept to production.

Pre-Test Analysis

During the pre-test phase, our engineers create a baseline FE modal to simulate the upcoming test and select optimal test conditions and output. Performing an initial pre-test analysis brings the following benefits:

- Evaluate modeling strategies

- Identify modeling errors

- Failure detection

- De-risk upcoming tests

- Select sensor: type, quantity & locations

Test – Analysis Correlation

During the correlation phase, the test results are compared to the FEM predicted values, studying the differences. The model is then adjusted to match the physical test results to improve its predictive ability by performing the following:

- Compare Test & FEA setup and results

- Adjust FEM material models, loads, and boundaries

- Identify localized modeling improvements

- Adjust modeling simplifications

- Run Analysis again to confirm improvements

Let’s Talk About Your Needs

See how our advanced engineering services can bring value and innovation to your project.